Premium Gala Pelletizer Blades

| Engineered for maximum performance in underwater pelletizing systems. Trusted by industry leaders worldwide for over 40 years. We supply Gala Pelletizer Blades that extend production runs, cut costs, and deliver more sales and higher profits.

40+

Years Experience6,000+

Gala Systems Worldwide99.9%

Quality GuaranteeGlobal

Customer SupportSolving Critical Underwater Pelletizing Challenges

Our precision-engineered Gala blades eliminate common production issues

that cost manufacturers time and money

Tail Formation

Problem: Poor blade geometry creates tails and sprues

Solution: Precision ground double bevel design ensures clean cuts

Frequent Replacements

Problem: Standard blades wear out quickly

Solution: M2 steel construction extends blade life 3x longer

Production Downtime

Problem: Blade failures cause costly shutdowns

Solution: Reversible design doubles blade life, reducing changeovers

Rising Costs/span>

Problem: Budget blades increase total cost of ownership

Solution: Premium materials reduce cost-per-cut by up to 40%

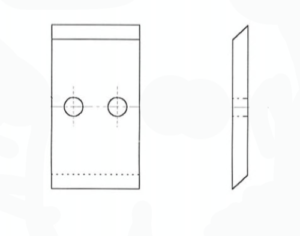

Features and Benefits of our replacement Gala Pelletizer Blades

- Manufactured from M2 steel or stainless steel to prevent rust and corrosion

- Double bevel pelletizer blades to offer reversible use

- Can be manufactured with different number of holes, slots, angles

- Coatings can be applied on custom request

Special lead times for custom-made pelletizer knives - Precision grinding technology for clean cuts without tails

- OEM standards manufacturing with customization options

- ISO9001 certified production facility

Blades Technical Specification

Specification

Details

Material Option

M2 High-Speed Steel (HRC 62-64), 316L Stainless Steel (HRC 58-60)

Blade Configuration

Double bevel, reversible design with custom hole patterns

Dimensional Tolerance

Tolerance ±0.001″ thickness tolerance, ±0.0005″ edge parallelism

Surface Finish

Ra 0.1-0.2 μm cutting edge, ground to mirror finish

Compatible Systems

All Gala underwater pelletizers, MAAG Group equipment

Quality Standards

ISO 9001:2015 certified, 100% dimensional inspection

Coating Options

TiN, TiAlN, DLC coatings available on request

Industry Applications

Optimized for diverse polymer processing applications across multiple industries

Polymer Production

Polymer Production

Primary pelletizing of virgin polymers including PP, PE, PS, PET, and engineering plastics

♻️ Plastic Recycling

Processing of recycled materials with varying contamination levels and melt properties

🎨 Masterbatch Production

Color and additive concentrate manufacturing requiring consistent pellet quality

🔬 Compounding Operations

Specialty compounds and filled polymers with abrasive additives and reinforcements

🏗️ TPE Processing

Thermoplastic elastomers and flexible compounds requiring precise temperature control

⚕️ Medical Grade Materials

Pharmaceutical and medical device polymers meeting strict purity requirements

The most common issue is the blade dullness, resulting from the regular use. The pelletizer must work harder, causing increased noise, vibration, and higher energy consumption. It is important to sharpen your blades or order a new set to avoid further damage.

Yes, please email us your issue, and our experts will be happy to discuss this further.

You might be interested in..