Precision-ground Vertical Form Fill Knives

Fernite manufactures vertical form fill seal knives for various markets: food, drinks, tobacco, pet food, chemical, medical, and pharmaceutical. Our vertical form fill knives always meet your exact bagging, heat sealing, and packaging requirements.

Form Fill Knives are among the most important VFFS machine parts and therefore should always provide reliable performance, we manufacture them from only the highest quality, fully traceable European steel.

- To improve wear resistance and prevent adhering, we can coat VFFS knives with Tin or Teflon coatings

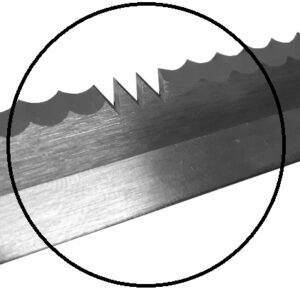

- Our advanced technology enables us to combine a huge variety of tooth profiles and pitches

- We offer customized FFS knives with tear notch knives that provide secure seals and easy-to-open

VFF and seal knives compatible with Bosch, Endoline, Fuji, Gainsborough, Hayssen, Ishida, Illapak, Krones, Maidstone, Matrix, Multivac, Omori, Redpack, Rovema, Syntegon, TetraPak, Wrights, Woodman and many more are manufactured by Fernite and supplied all around the world.

Rovema, Bosch, and Sandiacre are among our most popular ready-made VFFS blades

Custom and Popular Rovema VFFS

High Quality Bosch VFFS Parts

Popular Straight Teeth Sandiacre Bagger

Quality Hayssen VFFS Knives –

If you have a bespoke enquiry, or if you want to discuss your options with a member of our expert team, please email sales@fernite.com

Questions we get about our Vertical FFS Machine Packaging Knives

What are the best products to pack by Vertical Form Fill Seal Machine

The flexibility and efficiency of Vertical Form Fill Seal (VFFS) packaging machines make them a popular choice for a wide range of packaging applications:

Chips, popcorn, candies, and other snack products

Rice, grains, lentils, and other dry food staples

Ground coffee, coffee beans, and tea leaves

Various powders such as flour, sugar, spices, and powdered beverages

Frozen vegetables, fruits, potato chips

Shampoo sachets, soap bars, and other personal care products

Small hardware items, screws, nuts, and bolts.

Granular or powdered chemicals, fertilizers

Compare horizontal versus vertical packaging knives

- Appearance:

Horizontal – tooth knife and anvil knife (2 parts). The tooth knife goes against the anvil knife.

The tooth knife wears out faster than the anvil one.

Vertical – straight knife (no anvil)

- Mounting options

In horizontal – straight knife that usually mounts on the drum by two holes on the edges.

In vertical – has additional holding / mounting triangle on the top

- Tooth sharpness

Vertical packaging knives have sharper teeth than horizontal ones, as they need to punch through the vertical film.

As horizontal packaging tooth knife goes against the hard anvil and experiences a double clash, it does not need to provide extra sharpness.